Provide hardware surface powder spraying, surface paint treatment, electrostatic powder spraying and other processing business.

In the process of sheet metal processing, surface treatment is one of the processing steps. We can improve the service life of products in harsh environments or achieve specific surface effects or functions by surface treatment of sheet metal parts.

Common sheet metal processing surface treatment methods are as follows:

1. Polishing

Pre-polishing is the process of treating a polished stainless steel sheet metal surface with a hard or harder buffing wheel, which removes rougher marks on the surface. Fine polishing uses softness to further process the pre-polished surface, remove the traces left by the pre-polishing, and obtain a bright mirror surface.

2. mercerized

The mercerizing effect is the process of using the brushing wheel installed on the grinding and polishing machine to process the surface of the stainless steel sheet metal to obtain decorative silky brushing and satin finishing effects.

3. Sandblasting

Sandblasting effect, use compressed air flow to spray sand or steel shot, glass shot and other abrasives on the surface of stainless steel sheet metal processing, so that it appears a beautiful, slightly rough sandy surface.

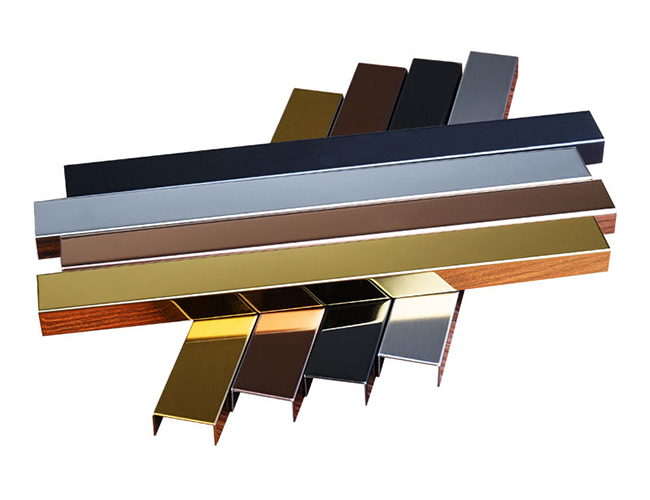

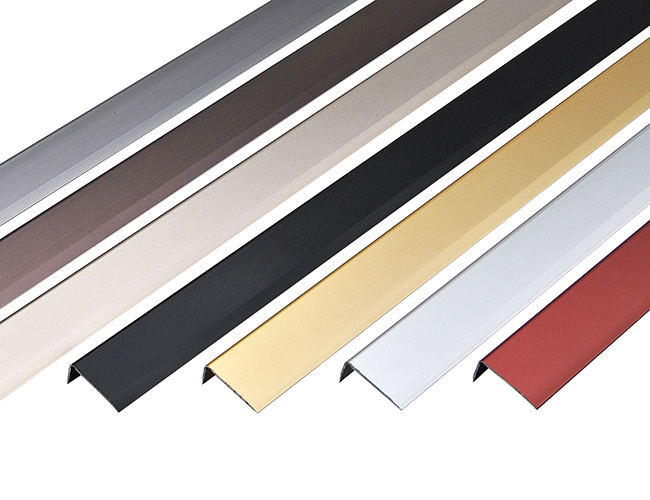

4. Baking paint

By spraying, high-temperature baking, etc., a layer of paint of various colors is sprayed on the surface of sheet metal processing materials to beautify the appearance and increase the anti-corrosion performance of the material. and powder paint).

5. Electroplating

Through chemical reaction, a layer of other metals is attached to the surface of sheet metal processing materials to increase the corrosion resistance of the metal and achieve a certain beautification effect.

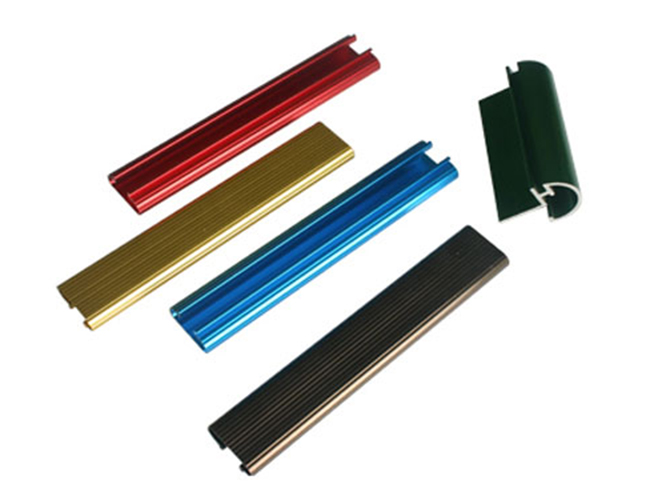

6. Anodizing

Oxidize the metal on the surface of the sheet metal processing to form a dense protective film on the surface of the workpiece to increase the corrosion resistance of the workpiece. Generally, there are two methods of chemical oxidation and anodic oxidation.

When we perform surface treatment on sheet metal processing, we need to select the corresponding surface treatment method for sheet metal processing parts of different materials according to their characteristics.

Matters needing attention in surface treatment:

First, pay attention to the state of the artifact. All electrochemical treatment must be carried out in the loose state of the workpiece parts, and it is considered that the parts cannot be electrochemically treated. Because during processing, the solution is trapped in the crevices of the part and corrodes the workpiece.

second, pay attention to the pretreatment before surface treatment. For example, steel needs to be phosphating before coating, which can improve the adhesion of the coating. To improve corrosion resistance, clear nickel plated steel can be first plated with copper or dark nickel. Zinc-based alloys also have this problem, requiring copper or deep nickel plating before plating to improve plating adhesion.

Third, pay attention to the fact that the workpiece material does not conflict with the processing method, and aluminum castings must not be anodized with sulfuric acid.

Fourth, whether the part is suitable for electrochemical machining should be judged according to the shape of the part. For example, thin tubes longer than 2 diameters are not suitable for electrochemical processing. Due to the inability to form a high-quality film on the inner surface, parts with deep grooves and pores deeper than twice the diameter cannot completely cover the inner surface after electroplating.

Fifth, pay attention to whether there is a conflict between the substrate and the coating material. Many organic gases are corrosive to zinc, so in sheet metal fabrication designs, galvanized layers should be carefully chosen to be in contact with organic materials or assembled in the same seal.

Some of the sheet metal processing materials are not resistant to corrosion, and oxidation reactions can easily occur, and the corrosion will continue to deepen. Cause sheet metal parts to lose performance or be scrapped. Therefore, it is necessary to achieve the purpose of anti-corrosion and rust prevention through surface treatment. The company has a set of advanced large-scale spraying equipment and standardized processing lines, which can provide professional surface processing for industrial equipment, chassis, cabinets, hardware, etc.